The quality of your product is our main concern

Being one of the largest European millers, we set the bar very high in terms of quality and food safety. Our craftsmanship and our modern production facilities combined with a comprehensive quality management system allow us to get the best out of grain.

Craftmanship

Our craftmanship is characterized by worldwide grain purchases based on extensive knowledge on grains and applications, market expertise and well-studied milling and handling techniques.

In addition, we offer you the possibility to benefit from the expertise of her highly qualified staff members in supplying added value with tailormade natural products. Only the best is good enough! Also, Dossche Mills makes sure to follow up continuously market trends and customer requirements. As such, our employees collaborate closely with our customers, industrial experts and internationally renowned organizations resulting in successful product renewals and process improvements.

Modern production facilities

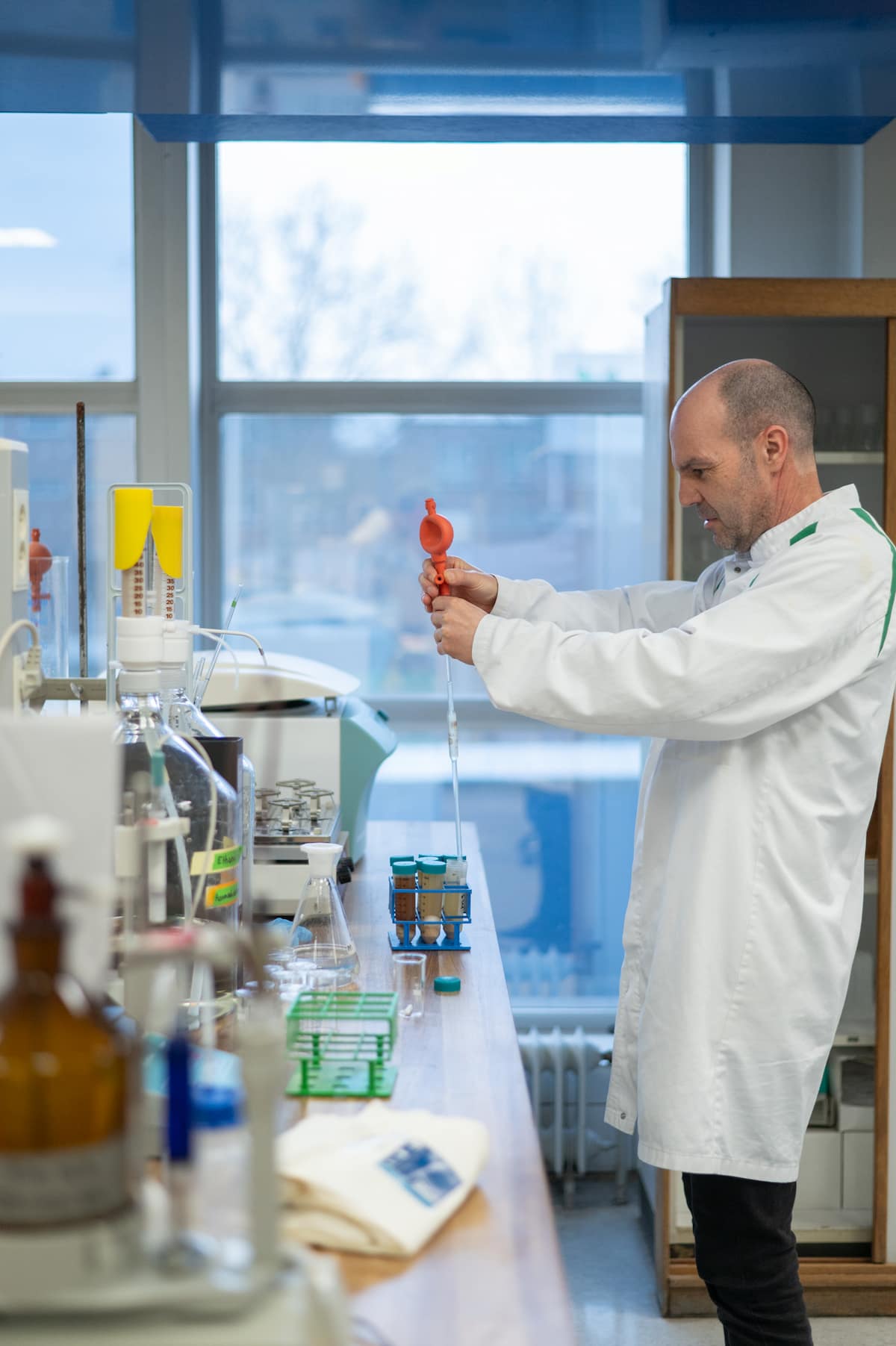

Modern production facilities support Dossche Mills in offering and expanding craftmanship and high quality: several grain/flour labs and test bakeries offer intensive quality verifications throughout the different phases of the production process.

Grain labortory

Each batch of wheat is subjected to extensive quality and safety checks before use. After the hygienic condition of the wheat offered has been approved, a whole series of tests follow to assess the baking properties. Based on these results, the optimal grinding and mixing of the grain raw materials is determined.

Flour laboratory

In addition to the grain, all other raw materials are also subjected to intensive quality and safety checks before use in production. At the same time, samples are systematically taken both during and after the production process to monitor the physicochemical properties of the flour and to adjust them if necessary. This is the only way to guarantee a stable end product with consistently high quality.

Pilot bakeries

The pilot bakeries or quality-control bakeries – where experienced bakers assess the baking properties of raw materials, production samples and flour products on a daily basis – are an essential part of internal quality control. At Dossche Mills, the technical baking experts are only convinced of the quality when they see and taste the result themselves.

Stable quality and authentic added value

Traceability is an important aspect for quickly identifying or mitigating problems, Dossche Mills uses this to continuously monitor wheat deliveries and to guarantee a stable, consistent quality of every grind. This way we can also add value to our products through authentic wheat varieties and specific origins.

Predicting the behaviour of dough

As the market leader, Dossche Mills believes it is a must to renew the analysis equipment in the laboratory every year. This way we can better predict the dough behaviour and baking properties of bread. The crowning glory here is the "Predict to Bake" device. This means that many more raw materials, intermediate products and end products can be assessed for their quality aspects in a much shorter period than via traditional techniques.

Legislation

Dossche Mills is aware that it has an important pedagogical role to play to help customers or suppliers on the right path when new legislation or regulations are introduced. The legislation is becoming increasingly stringent and as the market leader in the Benelux region and with a place in the European top 5, Dossche Mills believes that it holds a key position in informing suppliers and customers in a timely fashion.